|

Shanxi Dajinhua Magnetic Material Co.,Ltd.

|

Gold Index: 4933

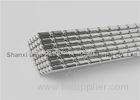

Sintered Rare Earth Magnets NiCuNi Coated Permanent Magnet For Generator

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sintered Rare Earth Magnets Special Magnets NiCuNi Coated Permanent Magnet For Generator<br

Sintered Rare Earth Magnets Special Magnets NiCuNi Coated Permanent Magnet For Generator

1. What is Neodymium Magnet

Neodymium magnets are actually composed of neodymium, iron and boron (they are also referred to as NIB or NdFeB magnets). The powdered mixture is pressed under great pressure into molds. The material is then sintered (heated under a vacuum), cooled, and thenground or

sliced into the desired shape. Coatings are then applied if required. Finally, the

blank magnets are magnetized by exposing them to a very powerful magnetic field in excess

of 30 KOe.

2. Disc N52 Permanent Magnet Details

| Item | 10 mm Disc Neodymium Industrial Motor Magnet With N52 Black Epoxy Coated |

| Shape | Hole Cylinder |

| Size | D6.5*D3.91*0.8 |

| Grade | N52 |

|

Plating |

Ni, Ni-Cu-Ni, Zn, Tin, Epoxy, Ni-Ag, Ni-Au, etc. |

| Material | NdFeB |

|

Working Temperature |

80 |

|

Application |

Motor Magnet |

3. More Choose

Grade:N33, N35, N38, N40, N42, N48, N50, N52 (M, H, SH, EH, UH,AH)

Shape:Disc, Ring, Block, Segment, Cylinder, Trapezoid, Customized Design (Design proper magnets for clients specific requirements)

Coating:Ni, Ni-Cu-Ni, Zn, Tin, Epoxy, Ni-Ag, Ni-Au, etc.

Plating Characteristics:

|

Plating Type |

Overall Thickness |

Salt Spray Test |

Pressure Cooker Test |

|

NiCuNi (Nickel Copper Nickel) |

15-21 μm |

24 hours |

48 hours |

|

NiCu + Black Nickel |

15-21 μm |

24 hours |

48 hours |

|

NiCuNi + Epoxy |

20-28 μm |

48 hours |

72 hours |

|

NiCuNi + Gold |

16-23 μm |

36 hours |

72 hours |

|

NiCuNi + Silver |

16-23 μm |

24 hours |

48 hours |

|

Zinc |

7-15 μm |

12 hours |

24 hours |

Each individual layer of Nickel and Copper are 5-7 μm thick. The Gold and Silver plating layers are 1-2 μm

thick.

Test results shown to allow comparison between plating options.

Performance in your application under your specific test conditions may vary.

Salt Spray testing conducted with a 5% NaCl solution, at 35 .

Pressure Cooker Test (PCT) conducted at 2 atm, 120 at 100% RH.

The different size, shape, surface coating for your choise.

Size customized; : Almost any size

Shape: Disc(Cylinder), Block, Ring, Countersunk, Segment and more, trapezoid, irregular shape, customized shapes are available

Surface treatment: Coating is an in alienable component of NdFeb magnets. It prevents these magnets from oxidation. Widely used coatings are Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chemical, PTFE, Parylene, Everlube, Passivation

Manufacture process

| Process No | Process details |

| 1 | Raw Matrial Preparation |

| 2 | VIM |

| 3 | Jet Milling |

| 4 | Compacting |

| 5 | Sintering & annealing |

| 6 | B-H Curve Testing |

| 7 | Maching |

| 8 |

Related Search

Rare Earth Permanent Magnet

Rare Earth Magnets Disc

Rare Earth Disc Magnets

Rare Earth Lifting Magnets

Rare Earth Magnets Sphere

Rare Earth Magnets Epoxy

More>>

Find more related products in following catalogs on Hisupplier.com

Company InfoShanxi Dajinhua Magnetic Material Co.,Ltd. [China (Mainland)]

Business Type:Manufacturer You May Like:

Printable Page

Bookmark this page

Sitemap XML About HiSupplier Help Center Customer Service Friend Links Site Map Archives Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español Copyright © HiSupplier.com Online Inc. All Rights Reserved.

|